| What is Earthing/Grounding? | |

| In fact, earthing/grounding is so important that it is the exact fundamental for any good protection system. It will ensure the protection of personnel and equipment from the dangers of lightning current. It is highly recommended to perform a check on the resistivity of the earth at most of the pre-determined locations. In the context of Singapore, for lightning earthing system, it is generally acceptable for resistance to be below 10 ohm. The acceptance level for equipment or signal earthing system is to be below 1 ohm. | |

| Maintenance and lifespan of earthing/grounding system | |

| It is critical to ensure that the earthing/grounding system that was first designed and installed, should be able to perform efficiently in years to follow. Resistance of the Earthing rods should be checked regularly. It is highly recommended to perform a yearly maintenance check of most earthing system using recently calibrated earth meter equipment. There are many factors that could affect the resistance of the earthing rods. For example, the moisture content of the ground, chemical composition of the soil and the temperature of the ground affect the resistance. | |

| How to achieve good grounding/earthing? | |

| This topic is perhaps one of the most “mystifying” subjects that will be highly discussed during most of the designing process. A good earthing/grounding system can be achieved by having low resistance conductors, good quality rods, plates, earth bars and joints. Other factors such as the nature of the Mother Earth or soil, temperature and weather do have a say in determing the resistance reading at the end of the day. | |

| Conductors | |

| The above can be considered as the most important component for both the earthing/grounding and lightning protection system. Depending different standards, it is necessary to choose the correct low resistance type of conductors. |  |

| Earthing Rods | |

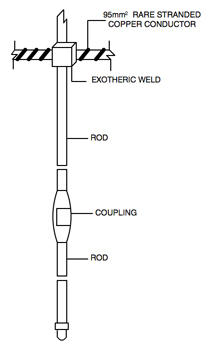

| Earthing Rods should be placed as deep into the ground as possible to achieve

overall low resistance. There are 3 main types of earthing rods, namely, Copper

Bonded, Solid Copper & Stainless Steel. Their usage are strongly subjected to the site

assessment. The dimension of the rods will also be useful for designing a good

earthing/grounding system. In Singapore, one common consideration for design of a

good earthing/grounding system will be the lack of space. Having numerous earthing

rods will not reduce the overall resistance unless adequate spacing between the rods

is maintained. One type of joint will be by exothermically fusion connection joint of bare copper cable to copper bonded earthing rod as shown below. |

|

| Earthing Compund Solution | |

| Earthing Compound like PMC is especially useful for bringing down the overall resistance of the earthing/grounding system. Some grounds have especially high earth resistance and is not easy to do any form of drilling works. In such cases, PMC will be able to provide a easy, convenient and permanent solution. |  |

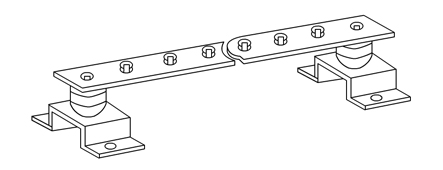

| Earth Bars | |

| Earth Bars are available in different dimension and hole patterns. It is critical to only have high copper content earth bars so as to achieve good earthing/grounding system. |  |

| Exothermic Welding | |

| This method of connection is just one of the many means of connecting conductors together. Exothermic connection is a fusion joint where it is a permanent connection with low contact resistance. A certain amount of immunity to corrosion makes it a suitable choice for environment that is near the sea. |  |